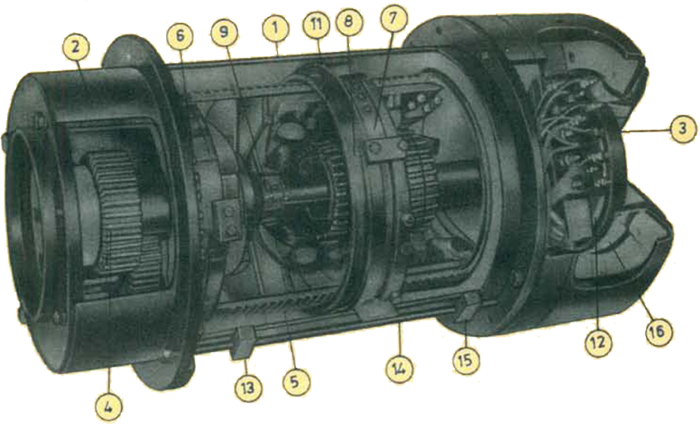

MAIN HOUSING : All hoist parts are enclosed in the main housing (1) thus forming a beteer looking integral uint.The main housing like the rope drum is also of rolled and welded construcion, equipped with mounting bracket.

ROPE DRUM : The rope drum (5) is rolled welded and precision machined. This rope durm is supported on large diameter roller bearings (6) on both ends and the drive is through internal gears. The ample durm diameter ensures the best possible working condition for the wire rope.

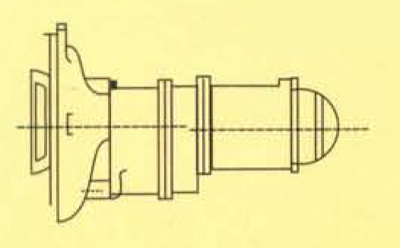

MOTOR : The motor (10) is three phase squirrel cage, conical rotor type working on 440 volts, 50 c/sec. A.C. supply. This motor is specially designed for hoist and crane and is insulated by class 'F' type 0 insulation according to B.S. : 2613. The starting and stalling torques of this motor are 220% and 290% of the full load torque. The motor is rated at 40% ED.

GEAR BOX : The gear box (2) is made out of high grade cast iron. The precision spur gears (4) are machined form alloy steel and are fitted with ball! needle roller bearings. The gear box is filled with grease.

BRAKE : The axial movement of the rotor is one of the characteristics of the conical rotor type of motro. This characteristic is taken advantage of in the actuation of the brake. When the motor is started the rotor (11) is axially pulled into the magnetic centre of the stator and the brake is released. As soon as the current is cut off the brake spring (9) presses the brake disc (12) against the cover and the brake is applied. The braking torque is 100% above the motor torque ate the rated load. The maintenance and adjustment of the brake is very simple due to system and can be done without removing any part. The brake disc and brake end cover (3) are both made of high grade cast iron and the brake lining is of 'Ferrodo' type.

ROPE GUIDE : The rope guide (7) is made of high grade cast iron. The rope tightener (8) is built-in the rope guide itself. This rope guide moves on the drum like a nut and prevents the rope form overriding and loosening.

LIMIT SWITCHES : Every hoist is provided with built-in limit switches (16) to control the top and bottom positions of the hook. Tappets (13&15) can be adjusted to any position in between the range provided. These limit switches are actuated by the rope guide.

CONTROL : The hoist is controlled by a pendant pust button station. Supply to the pendant pust button is of 110 volts as per IS specification.

ROPE : Generally 6x37 construction fibre core, pre-formed type, ungalvanised wire rope is supplied. (Galvanised and steel core wire ropes can also be supplied, if specifically asked for.)

MICROSPEED : All hoist can be fitted with a micro speed attachment which reduces the hoisting speed to 1/10 the of the main hosting speed. The micro speed attachment works independent of the load and main hoist. There is a ssparate control for the micro speed. This arrangement is invaluable in the handling of bulky, heavy and delicate loads.

TESTING : Every hoist unit before despatch is tested at 125% of the rated load capacity on single fall of rope. Only after all the components pass the rigorous inspection tests, the hoist is approved for despatch.

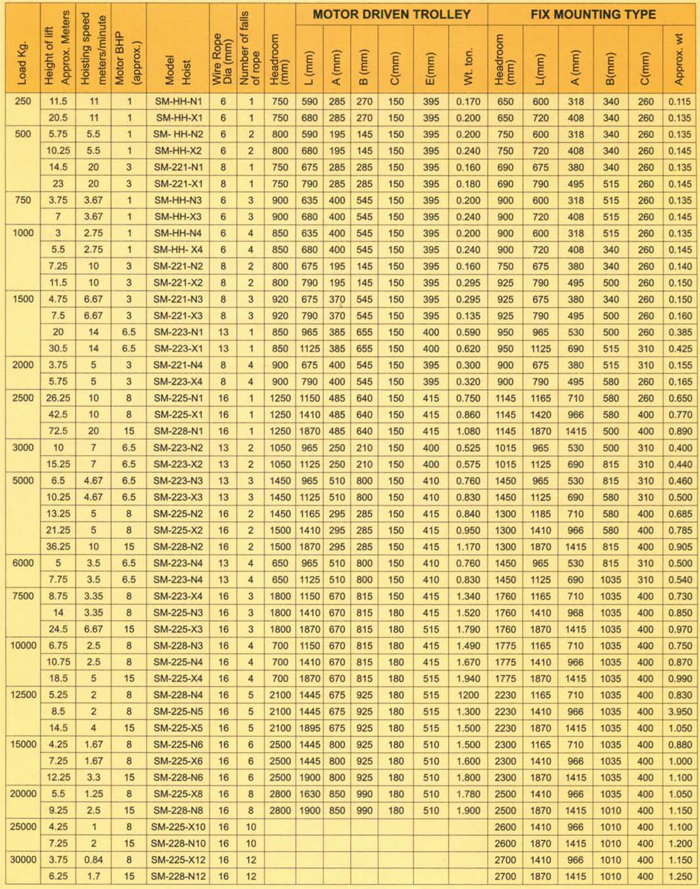

NOTE :

Above specifications can be modified to meet individual requirement. Dimensions are subject to change without notice.

Dimensions not indicated can be furnished on placement of order.

Dimensions of flexible trolley for hoist to run on curved beam can be furnished on request

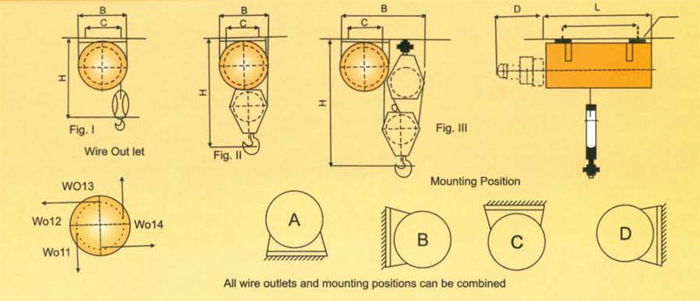

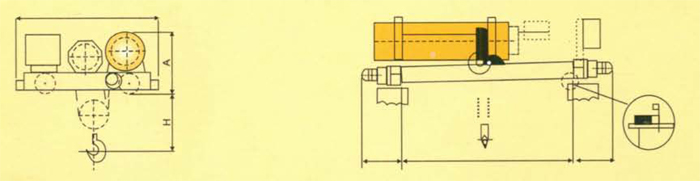

FIXED MOUNTED HOIST

These are available in all types of mountings, e.g. floor mounted, ceiling mounted, wall mounted etc. They are used for loading and unloading transportation vehicles, through floor hatches or outside the wall, and for serving production machinery.

When ordering, please state in what position the hoist is to be mounted and wire outlet (WO) required.

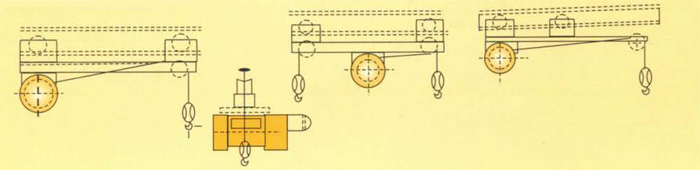

HOIST WITH TROLLEY

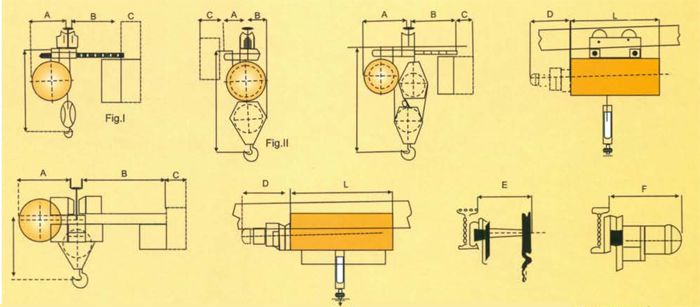

Hoists can be quipped with trolley for horizontal traveling, The trolley is fabricated from components. bolted and welded together and carried by traveling wheels supported on ball bearings. Similar loads can be moved with a push type trolley whilst the hand chain or motor driven should be used for heavier loads.

The motor driven trolley would be the best solution of the hoist unit is required to move loads rapidly.

The drive motor is of squirrel cage type with built-in brake.

The motor drives one or more of the trolley wheel's gear rim.

Wherever there are limitations to the available head room (dimension H), short head room trolley can be supplied (refer figure IV above.)

HOIST ON FLEXIBLE TROLLEY

Where the trolley has to negotiate a curved track, or the material movement is from on bay to another, this type of arrangement fulfils the requirement.

The minimum radius of curvature the flexible trolley can negotiate is 1.5 meters.

EXTENDED TROLLEY

These are particularly required when the load is bulky or for handling material from furnaces/chemical baths. This trolley can also be provided with two hooks to deal with loads like paper rolls, logs etc. When the loads go beyond the overhead track, an outrigger type of extended trolley is indispensable. These are used for loading on and unloading form ships in stream. Driver's cabins can also be built with the trolley.

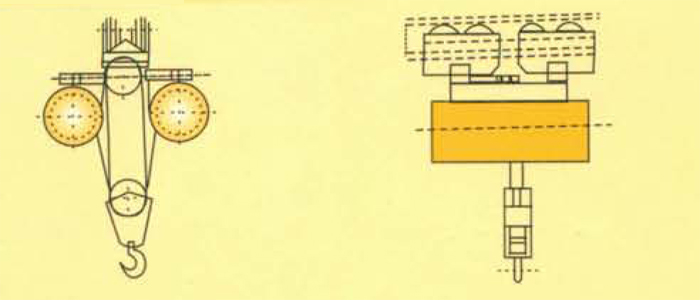

CRAB

Crabs can be supplied as standard units or can be custom made. They offer maximum advantage when working in open. These crabs can have single or twin hoist units as required. The driving arrangement can either be with hand-geared or motor driven type. Micro speed arrangement in hoisting can be provided if required.

TWIN HOISTS ON MONORAIL TROLLEY

For exceptionally high heights of lifts this arrangement if very useful. It also offers the option of two hoisting speeds. The maximum heights of lift is 73m for a load of 5 tonnes, for 288 type twin hoists.

MICRO SPEED ATTACHMENT

This attachment when fitted to the hoist can provide 1/10 the of the hoisting speed of main hoist independent of the load. A Separate push button interlocked with the main hoist push button controls the attachment. Thus either of the two can be operated at a time.